The Science of Lawn Mower Carburetors: Power and Precision

Introduction

A workhorse among the tools used to achieve well-manicured lawns is also one of the smallest creatures that lie within its heart — a carburetor in lawn mowers. This easily forgotten piece is tasked with combing through air and fuel at the perfect ratios to make your engine function. Science of Lawn Mower Carburetors Helps Keep Your Grass Short!Maintaining Power And Precision in Slice and Dice land. This post is all about the carburetor, how they function and what we can expect for the future of this essential part.

How Carburetors Work

The main function of a carburetor is to control the air-fuel ratio needed by the engine. The carburetor make the fuel mix with air in such a way that, when the throttle is opened or closed, opens their case and inserts more gasoline so it will depend on how much power gives, thus creating an ideal mixture for combustion cleanly. All this happens through a series of vents, jets and chambers inside the carburetor which in turn helps is delivering fuel precisely to cylinders present in an engine.

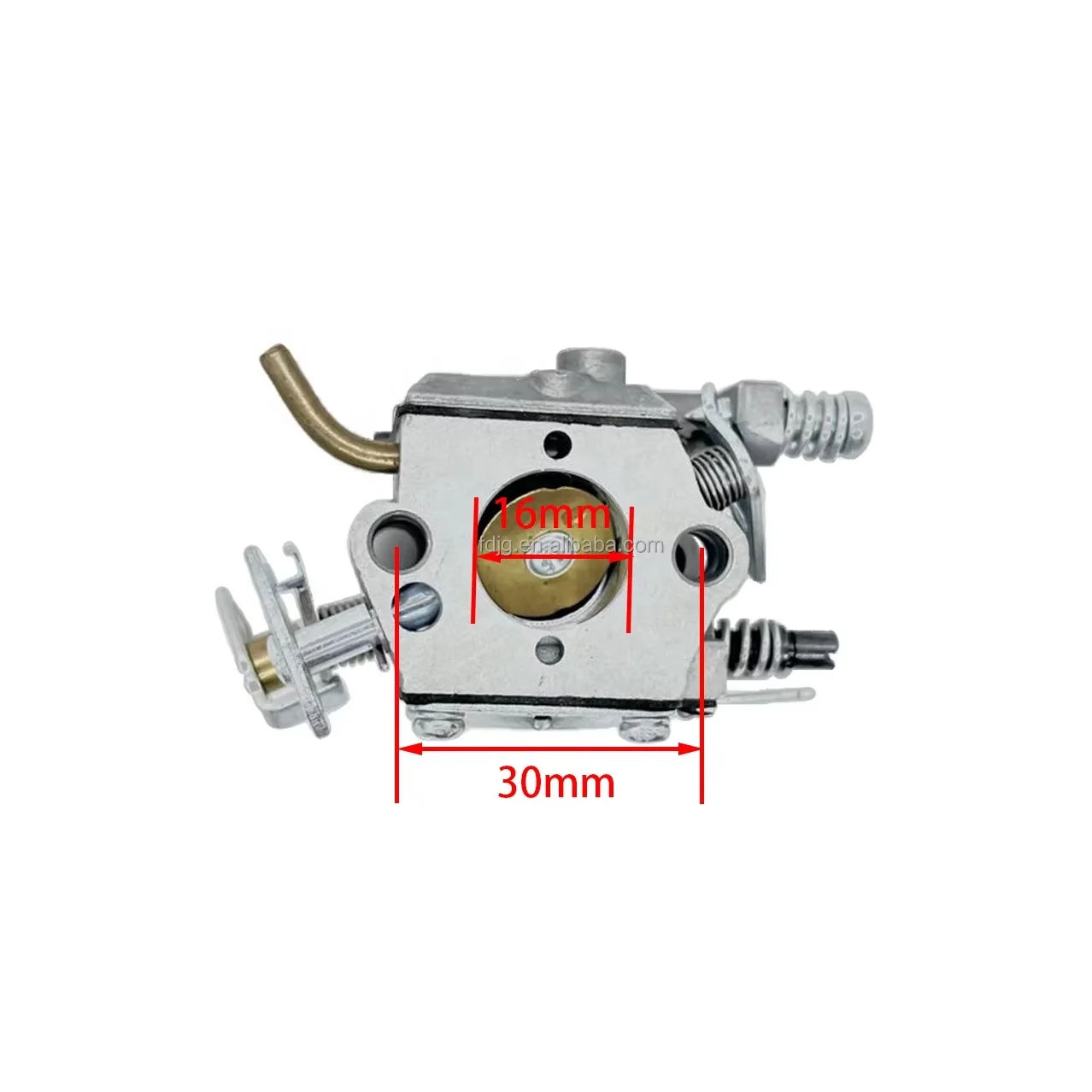

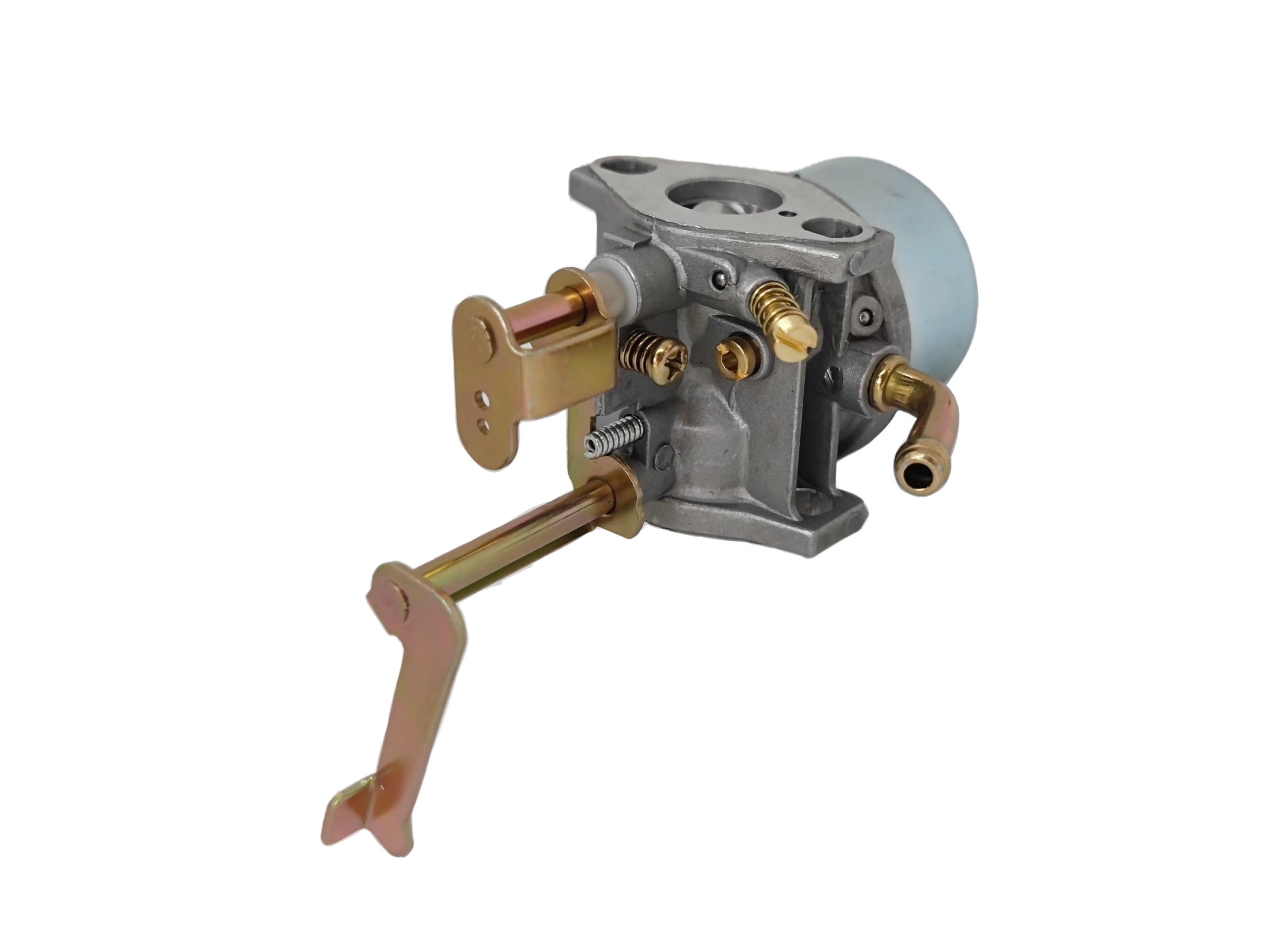

Different Kinds of Lawn Mower Carburetors

Types of Carburetor Used in Lawnmower

Fly wheel Variety of Carburetors: Float-type carburetor is afloat controlled valve, in which the float moves the fuel level inside and outside the carburetor. These are very dependable and cost-efficient, but they might have to be serviced more regularly.

Diaphragm type – Uses a flexible diaphragm to control fuel and provide better performance, improve idle over typical float-type carbs.

They are common with modern electronic fuel injection (EFI) systems and typically offer much more precise control over the amount of the air/fuel mixture, as well as improving low-end torque. The EFI system also improved engine response in contrast to traditional carburetors and generally made for better fuel efficiency and reduced emissions from vehicles that use these types of systems versus those using regular carburetors or throttle body injection devices a few years later on cars since 1988 even gone down second further closed loop knock circuit input in hybrid combustion carbon atom.

Elements that Effect Efficiency Of A Carburetor

There are a variety of factors that can influence how well you carburetor will work, including:

Air-fuel mixture ratio-should be well balanced for better engine performance. The wrong blend can result in sluggish operation or cause engine problems.

The initial engine startup also uses the choke system to increase fuel mixture when cold to be able start.

Changes in the carburetor are usually required as they can be stained by altitude and temperature for better performance.

A clogged carburetor- A filthy carburetor can cause a variety of problems from bad jack up, to stop working at idle speeds on (offroad go-kart) and even fuel woodworking when applying the throttle helping remind us how important routine support tasks are done.

Fix and Maintain

If you keep your carburetor clean, it shouldn't give you any problems.read Asset Up to fail: Why carburertors get dirty… How does a Dirty Carb cause hard starting?

Regular cleaning of the carb gets rid obstructions and helps smooth operations.

Adjusting the air-fuel mixture screw to further fine-tune engine operation.

Common problems like flooding or poor idle can frequently be traced to a dirty carburetor, and adjustment of the mixture screw.

Tuning for Peak Performance

Tuning carburetor is wherein the other parts are adjusted to produce right air-fuel mixture in loose terms, and straight away provide excellent engine performance. These might be as simple setting the idle speed screw, syncing gas and air by aligning throttle plates for silky engine response between speeds. A well-maintained carburetor will not only bolster performance, but it can also increase fuel mileage and lower emissions.

Environmental Considerations

Some of the emissions from a Carburetor are harmful to our atmosphere, and newer carb design is being made for improved emission pollution. The new era of greener technologies, like environmentally safe EFI systems aid reduction of lawn mower carbon footprints.

What Lies Ahead In The Future of Lawn Mower Carburetors?

Such as the evolution of carburetor technology to more EFI style systems that you see in normal cars, are set up replacing traditional carburetors for lawn mowers. These systems provide a number of benefits that improve performance, fuel efficiency and emissions. Higher-tech, greener future for lawn mower carburetors

Conclusion

A lawn mower is not possible without a carburetor, which means that the drive or precision of this equipment and will depend on it. Knowing how a carburetor works and taking proper maintenance steps with regular tune ups, paired with advances in technology keeps your lawn mower running the way it should. Take time to get know your lawn mowers carburetor and invest in keeping the equipment well or improve it will you have a better looking, greener healthier lawn while enjoying your outdoor space more!