Generator carburetors play a crucial role in your generator's performance. They regulate the fuel-air mixture, ensuring the engine receives the right balance for combustion. This process helps your generator run efficiently and deliver consistent power. Without a properly functioning carburetor, your generator may struggle to perform, wasting fuel and reducing reliability.

Cleaning and Maintaining Generator Carburetors

Start by turning off the generator and disconnecting the spark plug to prevent accidental ignition. Locate the carburetor, usually near the engine's air intake. Use a wrench or screwdriver to remove the bolts securing it. Carefully detach the fuel line and any connected hoses. Place the carburetor on a clean surface to avoid contamination. Take note of how each part is assembled to make reassembly easier later.

Spray carburetor cleaner on the exterior to remove grime. Use a small brush to scrub away stubborn dirt. Open the carburetor and inspect the internal components, such as the jets and float chamber. Spray cleaner into the jets and passages to clear blockages. Wipe the float chamber with a clean cloth. Ensure all parts are completely dry before reassembling.

Reassemble the carburetor by following the reverse order of disassembly. Reattach the fuel line and hoses securely. Mount the carburetor back onto the generator and tighten the bolts. Reconnect the spark plug and start the generator. Listen for smooth operation and check for any fuel leaks. If the generator runs steadily, the cleaning process was successful.

Installing or Replacing Generator Carburetors

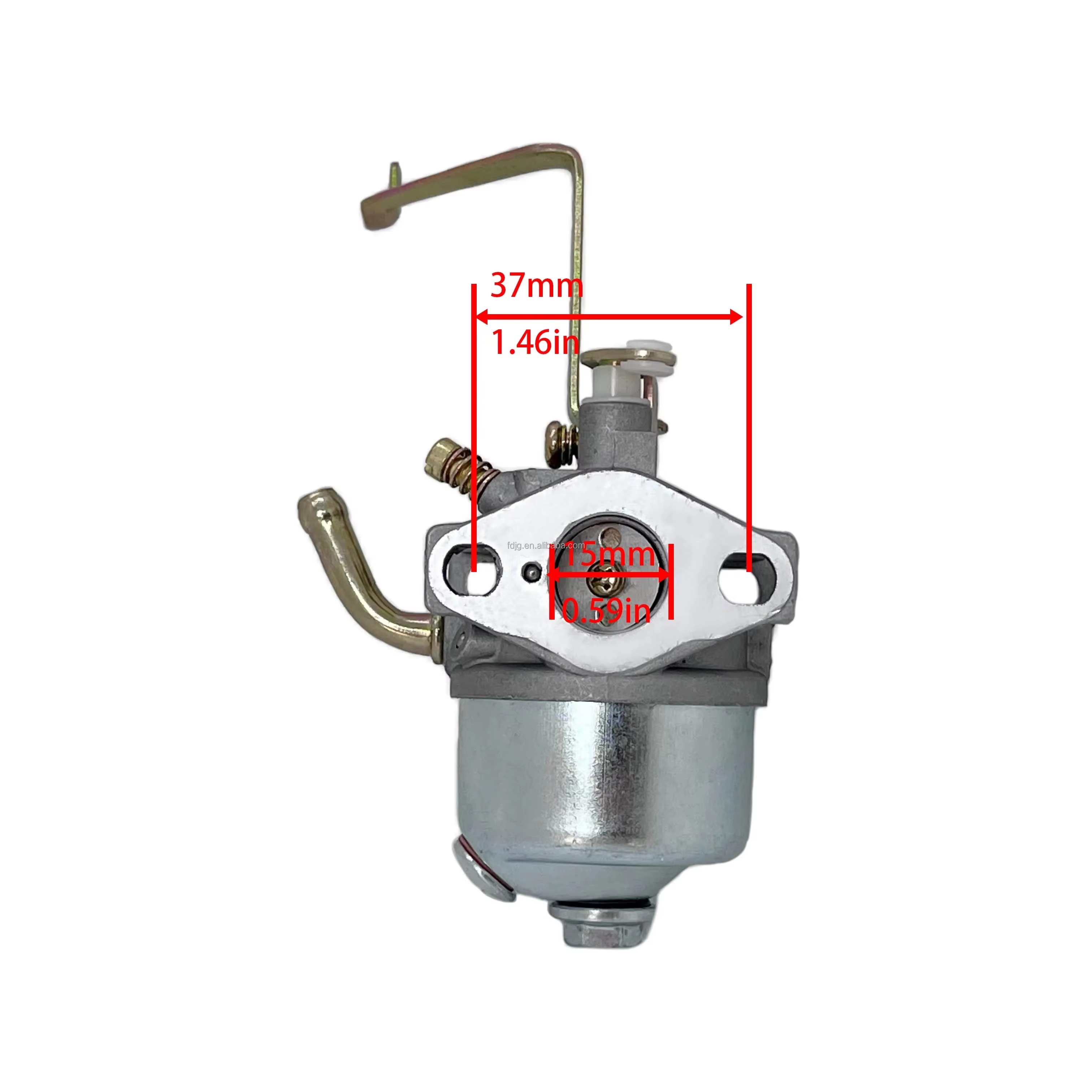

Selecting the correct carburetor for your generator

Choosing the right carburetor ensures your generator operates efficiently. Start by checking your generator’s manual for specifications. Look for details like the model number and engine type. These will help you find a compatible carburetor. If you don’t have the manual, inspect the old carburetor for identifying marks or numbers. You can also consult the manufacturer or a trusted supplier for guidance. Avoid using a mismatched carburetor, as it may cause performance issues or damage the engine.

Removing the old carburetor

Before removing the old carburetor, turn off the generator and disconnect the spark plug. This step prevents accidental ignition. Drain any remaining fuel from the carburetor to avoid spills. Use a wrench or screwdriver to loosen the bolts securing it to the engine. Carefully detach the fuel line and any connected hoses. Keep track of all screws and parts to make reassembly easier. Place the old carburetor on a clean surface for inspection or disposal.

Installing the new carburetor

Position the new carburetor in place of the old one. Align it with the mounting holes on the engine. Secure it with bolts, tightening them evenly to ensure a proper seal. Reattach the fuel line and hoses, making sure they fit snugly. Double-check all connections to prevent leaks. Follow the instructions provided with the new carburetor for any specific installation steps. This ensures the carburetor functions as intended.

Testing the installation for proper operation

Reconnect the spark plug and start the generator. Listen for smooth engine operation. Check for any unusual sounds or vibrations. Inspect the carburetor for fuel leaks or loose connections. If the generator runs steadily and delivers consistent power, the installation was successful. If you notice any issues, review the installation steps or consult a professional for assistance.

Common Issues with Generator Carburetors

Clogged jets or passages are one of the most common problems you may encounter with generator carburetors. Dirt, debris, or old fuel can block these small openings, disrupting the flow of fuel. When this happens, your generator may struggle to start or fail to run smoothly. Regular cleaning can prevent this issue. If you notice reduced performance, inspect the jets and passages for blockages. Using a carburetor cleaner can help clear these obstructions effectively.

Fuel leaks can occur due to worn-out gaskets, loose connections, or cracks in the carburetor body. Leaks not only waste fuel but also pose a safety hazard. You might notice a strong fuel smell or visible puddles near the generator. To fix this, check the gaskets and seals for damage. Tighten any loose fittings and replace faulty components immediately. Always address fuel leaks promptly to avoid further complications.

If your generator stalls frequently or idles roughly, the carburetor might be the culprit. This issue often arises from an improper air-fuel mixture. A clogged air filter or misadjusted throttle valve can also contribute to the problem. Inspect these components and clean or adjust them as needed. Ensuring the carburetor delivers the correct fuel-air ratio can restore smooth engine operation.

Conclusion

Generator carburetors are essential for efficient generator performance. They ensure consistent power and fuel economy. Regular maintenance prevents common issues and extends their lifespan. Troubleshooting helps you address problems early. Always prioritize safety when handling fuel or electrical components. With proper care, you can keep your generator running smoothly for years.