A chainsaw with properly tuned carburetors performs efficiently and safely. You reduce smoke and improve fuel efficiency by keeping the carburetor in top condition. This also prevents engine damage and extends the tool’s lifespan. Regular tuning ensures your chainsaw operates smoothly, saving you from costly repairs and unnecessary downtime.

Tools and Preparation for Properly Tuned Carburetors

Essential Tools for Tuning

To tune your chainsaw carburetor, you need a few basic tools. A flat-head screwdriver is essential for adjusting the carburetor screws. Some chainsaws may require a specialized carburetor adjustment tool, so check your user manual. A tachometer is helpful for measuring engine speed, ensuring precise adjustments. You should also have a clean rag or brush to remove dirt and debris from the chainsaw before tuning. Finally, keep a pair of gloves handy to protect your hands during the process.

Safety Precautions to Follow

Safety should always come first when working on your chainsaw. Wear safety goggles to shield your eyes from debris. Use gloves to prevent cuts or burns while handling the chainsaw. Make sure the chainsaw is on a stable surface to avoid accidental movement. Work in a well-ventilated area to prevent inhaling exhaust fumes. Always turn off the chainsaw and let it cool before making any adjustments. Following these precautions reduces the risk of injury and ensures a smooth tuning process.

Preparing the Chainsaw for Tuning

Before you start tuning, inspect your chainsaw for any visible damage. Check the air filter and clean or replace it if necessary. A clogged air filter can affect the carburetor's performance. Fill the fuel tank with fresh, high-quality fuel mixed with the correct ratio of oil. Start the chainsaw and let it run for a few minutes to warm up the engine. A warm engine allows you to make more accurate adjustments to the carburetor. Once the chainsaw is ready, you can proceed with tuning.

Step-by-Step Guide to Tuning a Chainsaw Carburetor

Warming Up the Engine

Start by warming up your chainsaw engine. A cold engine can lead to inaccurate adjustments. Turn on the chainsaw and let it idle for about 5 minutes. This ensures the engine reaches its normal operating temperature. If the chainsaw stalls during warm-up, restart it and slightly increase the throttle to keep it running. Once the engine is warm, you can move on to the next step.

Locating the Adjustment Screws

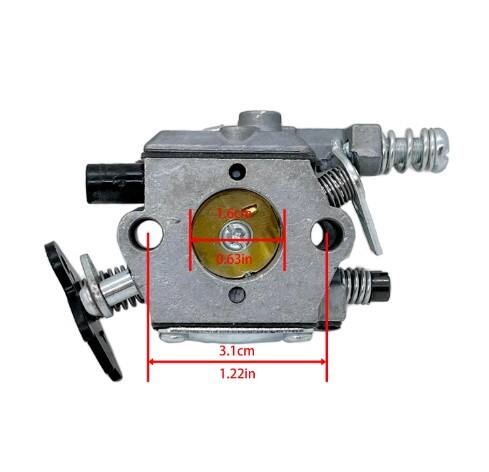

Find the carburetor adjustment screws on your chainsaw. Most models have three screws labeled L, H, and T. The L screw controls low-speed fuel flow, the H screw adjusts high-speed fuel flow, and the T screw manages the idle speed. Refer to your chainsaw’s manual if you have trouble locating these screws. Use a clean cloth to wipe away any dirt around the screws to prevent debris from entering the carburetor.

Adjusting the Low-Speed (L) Screw

Turn the L screw to fine-tune the fuel mixture for low-speed operation. Start by turning the screw clockwise until it lightly seats, then back it out one full turn. Gradually adjust the screw while listening to the engine. Aim for a smooth and steady idle without sputtering or stalling. If the engine sounds rough, make small adjustments until it runs smoothly.

Adjusting the High-Speed (H) Screw

The H screw controls the fuel mixture at full throttle. With the chainsaw running, press the throttle trigger to rev the engine. Turn the H screw clockwise until the engine reaches its peak speed, then back it off slightly. Avoid over-tightening, as this can cause the engine to run too lean and overheat. Use a tachometer if available to ensure the engine stays within the manufacturer’s recommended RPM range.

Fine-Tuning the Idle (T) Screw

Adjust the T screw to set the idle speed. Turn the screw clockwise to increase the idle or counterclockwise to decrease it. The goal is to achieve an idle speed where the chain does not move but the engine runs smoothly. If the chain starts spinning, back off the T screw slightly. A properly tuned idle ensures safety and prevents unnecessary wear on the chain.

Testing the Chainsaw for Optimal Performance

After making all adjustments, test the chainsaw under normal operating conditions. Cut through a piece of wood to check the engine’s performance. Listen for any sputtering or hesitation. A chainsaw with properly tuned carburetors should accelerate smoothly, maintain power, and idle without stalling. If issues persist, revisit the adjustment screws and make minor tweaks as needed.

Troubleshooting Issues with Properly Tuned Carburetors

Chainsaw Stalls During Operation

If your chainsaw stalls while running, the carburetor may not be delivering the right fuel mixture. Start by checking the low-speed (L) screw. Turn it slightly counterclockwise to increase the fuel flow. If the problem persists, inspect the air filter. A clogged filter can restrict airflow, causing the engine to stall. Replace the filter if necessary. Also, ensure the fuel you’re using is fresh and mixed correctly. Old or improperly mixed fuel can disrupt engine performance.

Engine Runs Too Lean or Too Rich

A lean engine doesn’t get enough fuel, while a rich engine gets too much. Both conditions can harm performance. If the engine runs lean, it may overheat or lose power. Turn the high-speed (H) screw counterclockwise to add more fuel. For a rich engine, turn the H screw clockwise to reduce fuel flow. Use a tachometer to confirm the engine operates within the recommended RPM range. This ensures the carburetor delivers the correct fuel-air mixture.

Overheating or Excessive Smoke

Overheating often results from a lean fuel mixture. Adjust the H screw slightly counterclockwise to cool the engine. Excessive smoke, on the other hand, indicates a rich mixture. Turn the H screw clockwise to reduce fuel. Check the muffler for blockages, as this can also cause smoke. Regular maintenance prevents these issues and keeps your chainsaw running efficiently.

Difficulty Starting the Chainsaw

If starting the chainsaw becomes difficult, the carburetor may need adjustment. Begin by inspecting the idle (T) screw. Turn it clockwise slightly to increase the idle speed. Check the spark plug for wear or carbon buildup. Replace it if necessary. Ensure the fuel is fresh and the air filter is clean. These steps often resolve starting problems and restore proper function.

Properly tuned carburetors play a key role in keeping your chainsaw safe and efficient. Regular tuning and maintenance prevent costly repairs and extend the tool’s lifespan. With the right tools and clear guidance, you can confidently handle this task. A well-maintained chainsaw ensures reliable performance every time you use it.