Carburatori generatori: la chiave per ottenere una potenza ottimale

Introduzione: Il potere dietro le quinte

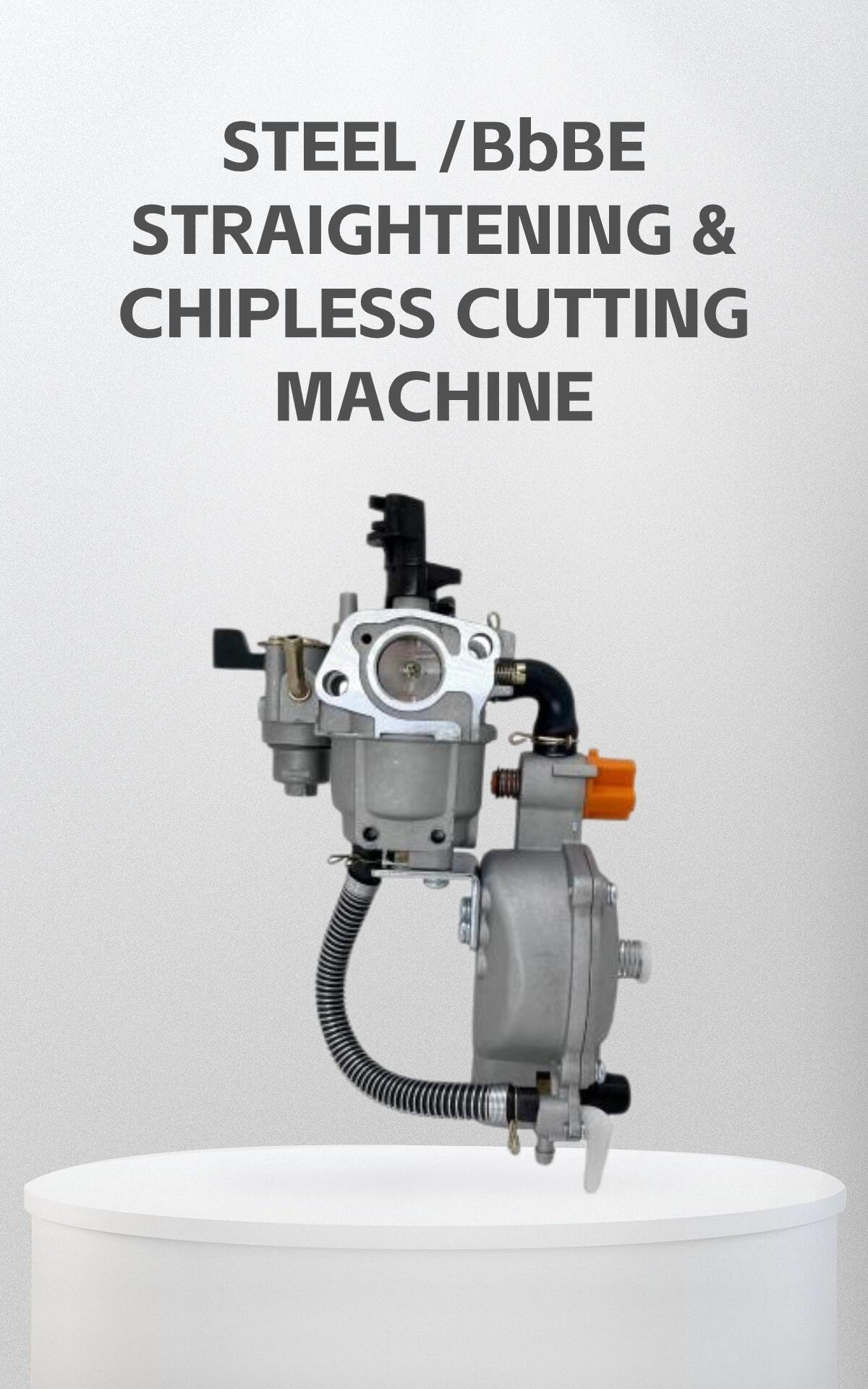

Ehi, appassionati di potenza! Vi siete mai fermati a pensare a come il vostro generatore continua a ronzare e a fornire la tensione richiesta da quegli importanti apparecchi quando è finita l'energia? In effetti, parlo dell'eroe non celebrato della produzione di energia, i carburatori generatori. Queste meraviglie meccaniche sono il segreto per ottenere la migliore potenza possibile, e in questo articolo discuteremo esattamente di cosa si tratta, come mantenerle funzionanti e dove possono essere impiegate nel futuro dell'energia.

Comprendere i carburatori: il cuore del motore

Bene, allora, cos'è un carburatore? Come se uno chef combinasse gli ingredienti per creare un piatto con proporzioni perfette; Nello stesso modo in cui hai bisogno di cibo e acqua per sopravvivere, un carburatore fornisce al tuo motore generatore cibo (carburante) e aria per farlo funzionare correttamente. Quindi, cosa sono i carburatori, ti chiedi? Bene, eccoci qui: analisi 1: diamo un'occhiata ai diversi tipi di carburatori:

Single Barrel Pensa a un solo artista con una sola voce: questa è la forma di base, utilizzata per i motori che sono sul lato più piccolo.

Twin Barrel: pensa a questo come a una coppia che canta in armonia. Questo tipo è per motori di medie dimensioni e dispone di due alimentatori per più potenza.

Multiporto: come un coro completo; per i motori più grandi, consiste di molti percorsi in cui il carburante e l'aria possono incontrarsi.

La cosa piu' importante e' che il carburante controlla il rapporto tra aria e carburante. Se esageri, avrai un motore a bassa potenza. Lottare per poco spazio di comunicazione, come voler correre una maratona a stomaco vuoto.

Il ruolo dei carburatori nei generatori: atto di bilanciamento

Quando si tratta di generatori, la parte principale del ruolo è svolta dai carburatori. Questi sono elementi chiave per fornire la migliore miscela aria-carburante necessaria per l'efficienza e le prestazioni del motore. Tuttavia, un carburatore è solo una parte del sistema di carburante. Faceva parte di una squadra e se non si prendeva cura di lei, poteva disturbarne il resto.

Un confronto facile è, se avete mai avuto un rubinetto che funzionava bene e poi si è intasato, come ha fatto l'acqua a fluire? Questo vale anche per un carburatore. Il filtro intasato può contribuire a una cattiva distribuzione del carburante portando il generatore a sputter o fermo. Manutenzione e cura: Qui si svolge la manutenzione, con la pulizia e la messa a punto che fanno funzionare il generatore come nuovo.

Miglioramento della potenza attraverso l'ottimizzazione del carburatore: messa a punto per il successo

E ora, discuteremo di come ottenere il massimo dal tuo generatore vestito da nove. Ha a che fare con le regolazioni del carburatore. Si può inserire ancora di più la miscela aria-carburante giocando con il getto e l'ago, regolandolo perfettamente per produrre la massima potenza possibile. Come accordare le corde di una chitarra per trovare perfettamente quella nota.

È disponibile anche una versione ancora più grande da 7,5 litri del V8, insieme a una modificazione opzionale dell'intacco d'aria che migliora l'efficienza. Pensate ad aprire una finestra in una giornata di vento porta aria fresca e allenta la stanza. Allo stesso modo, il generatore può essere migliorato permettendo più aspirazione d'aria per migliorare le sue prestazioni.

Conclusione: L'eroe sconosciuto merita di essere messo in luce

In sintesi, i carburatori dei generatori sono gli eroi non celebrati del funzionamento del vostro generatore. Non solo aiutano il motore ad essere più efficiente, ma contribuiscono anche in modo significativo al progresso della tecnologia dei generatori. La prossima volta che si accende un interruttore e si accende il generatore, si punta il cappello al carb. L'eroe non cantato, tempo di dargli il suo dovere e ricordarci quanto siano importanti la manutenzione regolare e le necessarie misure di sicurezza.

Restate con noi per altre storie sulla generazione di energia e assicuratevi di alimentare bene il carburatore. Dopo tutto, un carburatore felice equivale a un generatore felice!